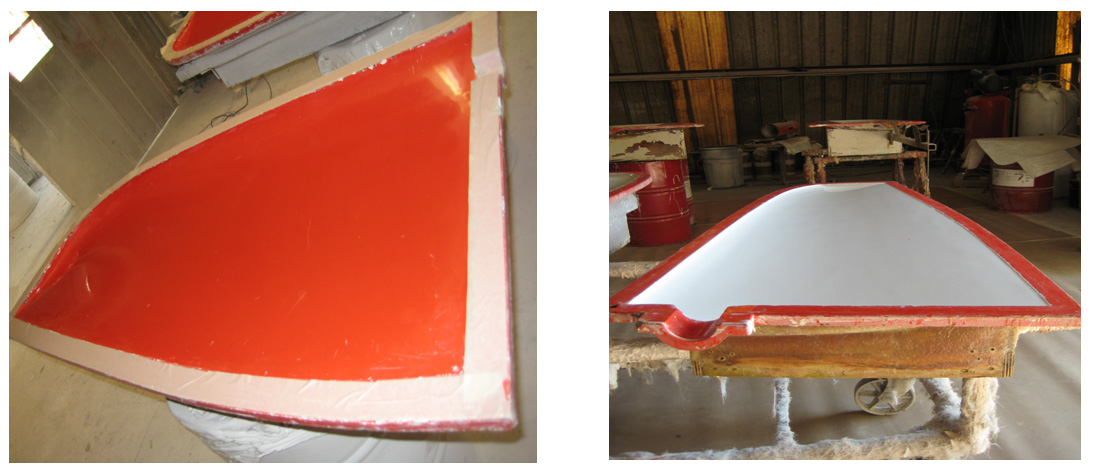

IMAGE ONE: Tape flanges and wax mold.

IMAGE TWO: Spray the mold surface with gelcoat.

IMAGE THREE: Lay-up material, one layer of 3/4 oz mat and two layers of 1808 unidirectional roving. Laminate three layers of 2 oz mat in the bottom radius.

IMAGE FOUR: Trim excess laminate. Scrape and wax flange.

IMAGE FIVE: Lay in steel making sure the post is tight inst the support and the pin is inserted in the locator hole of the frame.

IMAGE SIX: Wet out and roll two – 2″ to 3″ layers of2 oz mat along the trailing edge of each half. The area highlighted above.

IMAGE SEVEN: Mix and pour Foam. Foss Foam is a 20 pound per cubic foot closed cell urethane foam. Close and clamp mold.

IMAGE EIGHT: Cross cut section of a Foss Foam Rudder. This process occurs all in the same today to promote chemical bonding.

IMAGE NINE: Rudder just out of the mold with seam.

IMAGE TEN: Rudder trimmed and ready for seams to be glassed.

IMAGES ELEVEN & TWELVE: Rudders seam is glassed then sanded. Gelcoat is then applied to the entire surface.

IMAGES THIRTEEN & FOURTEEN: Rudder is sprayed with gelcoat.

Foss Foam Products of Florida, Inc. still blends its own 20 pound per cubic foot high density closed cell polyurethane foam. Foss Foam is the ideal product for manufacturing sailboat rudders.